Authors: Ema Vasileska, Ali Gökhan Demir, Bianca Maria Colosimob, *Valentina Gečevska, Barbara Previtali

Abstract

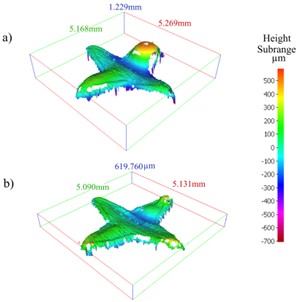

Common practice in Selective Laser Melting (SLM) is employing a series of fixed process parameters throughout the whole build. However, process thermal conditions strongly depend on the local geometry of the part. Formation of some common defects, including swelling regions and elevated zones, emerges in critical corner areas due to excessive heat accumulation when constant parameters are used. Adaptation of energy input according to the geometry of the processed zone is highly desirable for avoiding defect formation. To assess the processing conditions, observation of the melt pool and its variation as a function of the process parameters with a coaxial camera operating in near infrared (NIR) demonstrated to be a feasible option. This work develops an empirical model that gives the correct amount of energy input to achieve stable melt pool depending on the single vector length, hence the part geometry. The model was validated on a prototype SLM system, and the results showed that controlling the process parameters considerably improves the geometrical accuracy of the parts with sharp edges prone to hot spot formation.

Key words:Additive manufacturing, Geometrical accuracy, Melt pool monitoring, Process modelling, Energy input control;

DOI: 10.24867/ATM-2022-1-003