Authors: Izidor Sabotin, Marko Jerman, Andrej Lebar, Joško Valentinčič, Toni Böttger, Lisa Kühnel, Henning Zeidler

Abstract

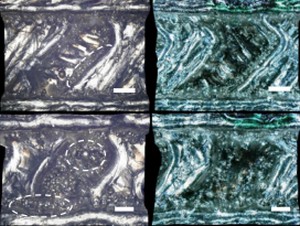

Additive manufacturing (AM) of metallic parts is gaining momentum in production industries. In view of producing a metal microproduct using AM the issue of high surface roughness is prominent. Plasma electrolytic Polishing (PeP) is a post processing technology that greatly reduces surface roughness of metallic parts. In this paper the effects of PeP of microfluidic platform, printed with selective laser melting (SLM) technology, is presented. The results show that surface roughness of the specimens was severely reduced. Also, some geometrical defects inherent to SLM technology were partly removed. It is shown, that for smaller geometrical microfeatures (sizes of less than 0.5 mm) the effectiveness of PeP is reduced. Through this investigation it can be concluded that PeP is a promising post-processing technology for SLM printed microparts since it significantly improves the overall part quality. However, further improvements of the process chain need to be implemented in order to render the microfluidic platform functional.

Key words:Selective laser melting, Plasma electrolytic polishing, Microfluidics, Additive manufacturing;

DOI: 10.24867/ATM-2022-1-004