Authors: Slaviša Djačić, *Srbislav Aleksandrović, Dušan Arsić, Marko Delić, Vukić Lazić

Abstract

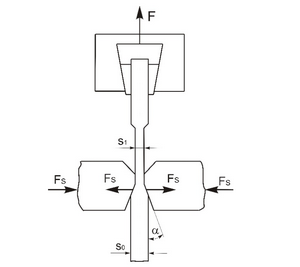

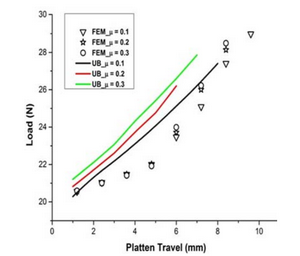

Comparison of application of constant and variable lateral force in strip ironing process with double side thinning are presented in the paper. Given are the experimental results for single and multiphase ironing process with constant lateral force during the course of particular process. Material used was mild steel DC04. Stripes were 20 mm wide and 2.5 mm thick. Constant lateral force intensities were 5, 10 and 15 kN. Lubrication was with appropriate mineral oil and grease. In other side given is analysis of idea of possibility to apply variable lateral force during the strip ironing process and consequences of this action. Expected is control of strip thickness variation with difficulties because of contact and other appearances influence.

Key words: ironing process, strip sliding test, variable lateral force;

DOI: 10.24867/ATM-2021-2-001