Authors: Aleksandar Čabrilo, Katarina Gerić

Abstract

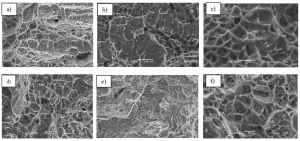

Welding of armored steel is complicated by the high percentage of carbon in the base metal, the presence of faults in the form of cracks and pores that occur in the weld metal and heat affected zone (HAZ) during the welding process. The crack formed in base metal or HAZ, due to dynamic or impact loads, can easily continue to propagate to the fusion line, after which its accelerated growth may occur. It was demonstrated that the selection of the preheating and interpass temperature is important in terms of the cooling rate and quantity of diffusible and retained hydrogen in the weld joint. Due to the significant interest in quantifying the resistance of material to initiation and propagation of cracks, the impact energy was measured with instrumented pendulum in the zone of base metal, weld metal and HAZ, at temperatures of -40 °C, -20 °C, 0 °C and 20 °C. The impact energy tests showed high energy for initiation as well as crack propagation in weld metal and HAZ zones, while the lowest energy was in the base metal.

Key words: GMAW welding, Armor steels, Austenitic stainless steel and Instrumented Charpy tests.

DOI: 10.24867/ATM-2018-1-003