Authors: Blaž Karpe, Mateja Vodlan, Igor Kopač, Igor Budak, Aleš Nagode, Alenka Pavlič, Tatjana Puškar, Borut Kosec

Abstract

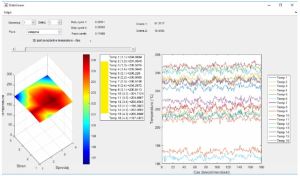

Today almost all manufacturers of dental materials in their certificates of material quality describe material chemical composition, mechanical properties, process ability and aesthetic characteristics, while information about thermal properties are not available. Within the interdisciplinary and international teamwork, thermal properties of five selected dental materials were measured, by modern transient plane source method in accordance with standard ISO 22007-2. Thermal properties were measured at temperature interval between 7 °C and 45 °C.

Key words: Dental materials, Thermal properties, Transient plane source (TPS) method, Measurement;

DOI: 10.24867/ATM-2018-1-002