Authors: Samir Butković, Emir Šarić, Muhamed Mehmedović

Abstract

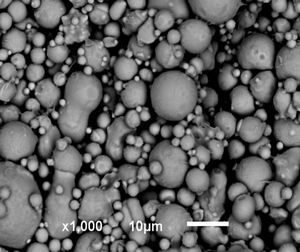

Metal injection molding technology is commonly used in production of small and very complex parts. Residual porosity is unavoidable characteristic of P/M parts, affecting their final properties. During injection molding phase powder-binder separation can occur, causing green density variation through cross section of the part. This behaviour is particularly pronounced as complexity of the parts increases. As a consequence, zones with different density and residual porosity can be seen after sintering. In this regard, porosity and hardness distribution of the sintered ring-shaped part is analysed and presented in the paper.

Key words:Metal injection molding, sintering, porosity distribution;

DOI: 10.24867/ATM-2021-1-002