Authors: Kayode I. Fesomade, Damilola D. Alewi, Saliu O. Seidu, Sheriff O. Saka, Bonaventure I. Osuide, Godwin C. Ebidame, Marybeth C. Ugoh, Damilola O. Animasaun

Abstract

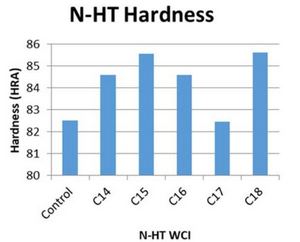

This study investigates the influence of palm kernel shell ash (PKSA) on mechanical and wear properties of white cast iron (WCI) particularly its influence on its microstructure, elemental composition, hardness and wear resistance. The PKSA was characterized to determine its elemental composition, and it was found to contain high amount of silicon (Si) and iron (Fe) followed by calcium (Ca) and other trace elements. The cast iron was cast into rods of specific dimension with sand casting method using rotary furnace to re-melt cast iron scrap. The WCI rods were then cut into bits for the various test. Heat treatment operation was carried out to determine its properties. Upon completion of the examinations, it was found that the PKSA increased the cementite phase within the matrix of the cast iron, and reduced the pearlitic phase and graphite formation, which gave it increased hardness, and perfect wear resistance due to the increment in carbon content and reduction in silicon content. Also, upon heat treatment, it was found that the PKSA reduced the pearlitic phase within the matrix of the cast iron, increases the formation of transformed ledeburites, austenitic dendrites and tempered graphite, which lead to increased machinability and ductility as well as to reduced hardness, and wear resistance when compared to non-heat treated samples.

Key words: Microstructure; Heat treatment; Wear Resistance; Hardness; palm kernel shell ash (PKSA)

DOI: 10.24867/ATM-2020-2-004