Authors: Helge Kügler, Frank Vollertsen

Abstract

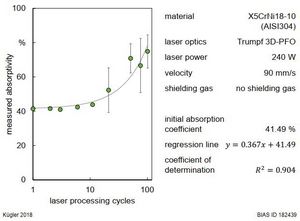

Material processing with laser beams is well-known in nowadays production. Compared to CO2 lasers, modern solid state lasers are, amongst others, popular because of higher energy efficiency and higher absorption when metals like steel and aluminum are irradiated. However, the absorption of metals is not only dependent on the chemical composition of the work piece metal and the laser beam wavelength. Previous investigations determined the oxidation of the surface as an influence on laser beam absorption changes due to multiple irradiation. In this study, a method is presented for considering the absorption coefficient changes caused by surface oxidation in numerical simulations. Reproductions of single trajectories were assigned with appropriate absorption coefficients calculated from a function generated by reference tryouts. With the described approach, benefits are gained for numerical simulations of laser beam forming (like bending) and other processes with an iterative heat input.

Key words: laser bending; absorptivity; iterative processes; simulation accuracy

DOI: 10.24867/ATM-2019-1-001